What Is Silicon Metal

Silicon, is a chemical element with the symbol Si and atomic number 14. It is a metalloid, meaning it has properties of both metals and nonmetals. Silicon metal, also known as crystalline silicon or industrial silicon. It is a product made from quartz and coke melted in an electric furnace. Its silicon content is above 98%. Other impurities are iron, aluminum, calcium and so on. Metallic silicon is mainly used as an additive for non-ferrous alloys.

According to the different applications, si metal can be divided into chemical grade metal silicon and industrial grade metal silicon. Silicon metal is divided into metal silicon blocks and metal silicon powder according to the different shapes.

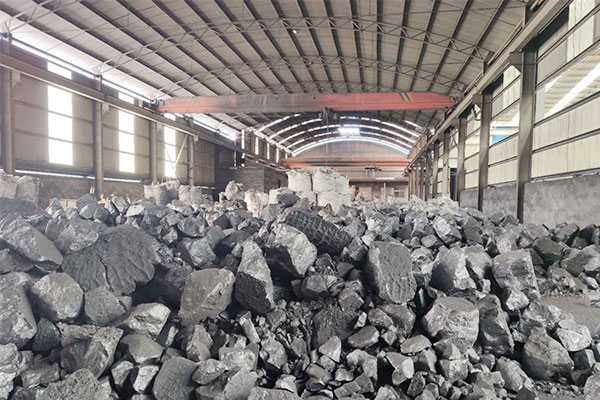

Silicon Metal Lumps

Metal silicon blocks provided by Foosoon, Si≥99.99%. From the selection of raw materials to the production process, all are controlled by professional and technical personnel. Impurities in metallic silicon can be minimized.

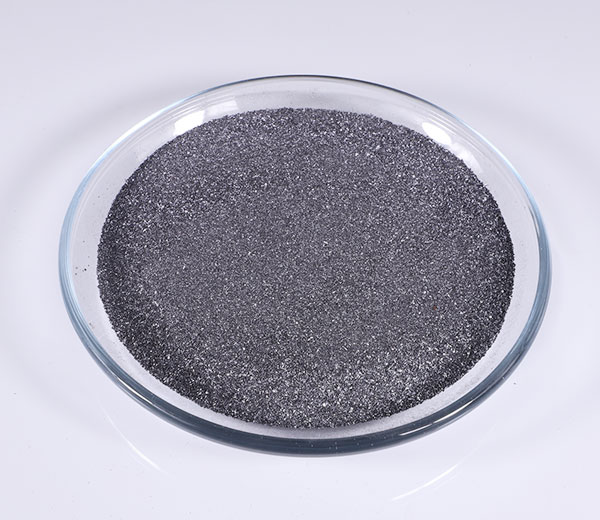

Silicon Metal Powder

Silicon metal physically grounded into very fine particles or powder, becomes silicon metal powder. It is also known as industrial silicon powder.

Silicon Metal & Powder Specifications

According to the content of iron, aluminum and calcium in silicon metal, it can be divided into 553, 441, 411, 421, 3303, 3305, 2202, 2502, 1501, 1101 and other different grades.

| Grade | Si | Fe | Al | Ca | P |

| 553 | 98.5 | 0.5 | 0.5 | 0.3 | – |

| 441 | 99 | 0.4 | 0.4 | 0.1 | – |

| 3303 | 99 | 0.3 | 0.3 | 0.03 | 25/40/60 |

| 2202 | 99 | 0.2 | 0.2 | 0.02 | 25/40/60 |

| 1101 | 99.2 | 0.1 | 0.1 | 0.01 | 25 |

| Off grade | 97 | 1.5 | 0.6 | 0.3 | |

| %min. | %max. | %max. | %max. | ppm |

Silicon Metal Production Process

In industry, The primary method for silicon production is the carbothermic reduction process. Metallic silicon is produced by carbon reduction of silicon dioxide in electric furnaces. Chemical reaction equation: SiO2 + 2C → Si + 2CO The purity of silicon produced in this way is 97~98%, which is called metallic silicon. Then it is melted and recrystallized, and impurities are removed with acid to obtain metallic silicon with a purity of 99.7~99.8%.

1. Preparation

The primary raw material for silicon production is quartz (silicon dioxide, SiO2). Other raw materials may include coal, wood chips, and iron.

2. Smelting

After the raw materials of silicon metal are ready, the electric arc furnace is heated and the raw materials are placed sequentially.

3. Casting And Cooling

When heated to the melting point, a metallic solution is formed. The solution is introduced into the prepared mold and cooled.

4. Broking And Packing

After cooling, the silicon metal is processed into block, granular, powder and other shapes. Then it is packed and stored.

What Is Silicon Metal Used For

Silicon metal finds diverse applications across various industries due to its unique properties, including its ability to conduct electricity, its thermal stability, and its contribution to the strength and hardness of alloys. Here are some common uses of silicon metal:

Why Choose Foosoon Silicon Metal

China serves as a global supplier of silicon metal, exporting to various regions around the world. China is a major producer of silicon metal and has significant production capacity. China has a long-standing presence in the silicon metal industry, with experienced producers and technicians. This expertise contributes to the quality and consistency of silicon metal products. Foosoon is a professional metal silicon trading supplier in China, choose us can help you find the right price and good quality metallic silicon products as soon as possible.