Cored Wire

Offer all kinds of cored wire. CaSi cored wire, C cored wire, CaFe cored wire and so on. High quality and stable supply.

What Is Cored Wire

What is cored wire? It is according to the user’s steelmaking requirements, the various element alloys are made into powder, and they are rolled into the steel belt through the equipment. It is used in the steelmaking industry to introduce specific alloying elements and additives into molten steel in a controlled and precise manner.

Types of cored wire

According to the different alloy powder can be divided into: CaSi cored wire, Calcium cored wire, CaFe cored wire, Carbon cored wire and so on. More commonly used are Carbon cored wire, Calcium cored wire and CaSi cored wire. Carbon cored wire is also called graphite wire, which is rolled with half graphite powder. Inside the silicon calcium wire is 6030 silicon calcium powder.

Cored Wire Specifications

| Model | Chemical Composition(%) | Wire Diameter(Mm) | Wire Thickness(Mm) | Wire Weight(G/M) | Powder Weight(G/M) | Uniformity(%) |

| Sica | Si55 Ca28 | 13.0 | 0.4 | 170 | 230 | 2.5-5 |

| SiCaBa | Si55 Ca15 Ba15 | 13.0 | 0.4 | 170 | 220 | 2.5-5 |

| CaFe | Ca 30-32 Fe68-70 | 13.0 | 0.4 | 170 | 215 | 2.5-5 |

| C | 90min | 95min | 98min | |||

Cored Wire Manufacturing Process

Cored wire is a product where powdered elements are tightly encased in steel sheaths and formed in round shape of various diameters, depending on the various requirements of the costumer and is supplied packed level-wound in steel cages. Take CaSi Cored Wire as an example. The main raw material of CaSi cored wire is silicon calcium powder. Then silicon calcium as a core material, the outer skin is steel. And then it is pressed by professional wire pressing machine.

Method of using cored wire

When used, the core wire can be inserted into the ideal position through professional wire feeding equipment. When the skin of the core wire is dissolved, the alloy powder inside the core wire can be fully dissolved in the ideal position and produce chemical reaction. In this way, the reaction with air and slag is effectively avoided. Thus, the absorption rate of smelting materials is improved.

Depending on the alloy powder inside, the cored wire can be used as deoxidizer, desulfurizer, and alloy additive. But the premise is that you must use professional wire feeding equipment. The wire feeding equipment can accurately control the feeding amount and feeding speed of the cored wire. Therefore, if there is no wire feeding equipment, it will be more troublesome to use.

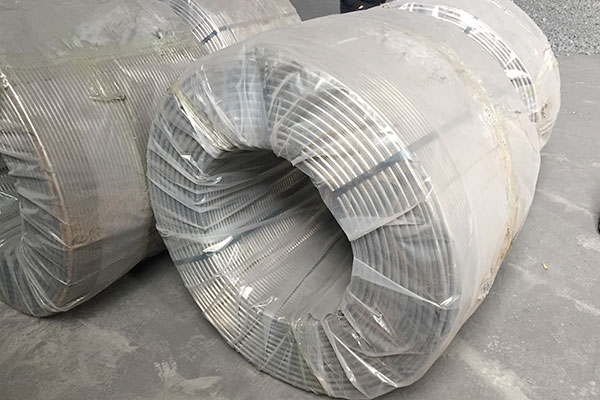

Packaging of Cored Wire

Horizontal and vertical two types of wiring.

What is Cored Wire Used For

Cored wire is mainly used in steelmaking. It is a means of auxiliary smelting steel. It has become a widely adopted technology in the industry to produce high-quality steels with specific properties tailored to customer needs.

The use of cored wire can purify the inclusion form of steel, improve the castability of molten steel and improve the service performance of steel. The use of cored wire can effectively improve the utilization rate of alloy and reduce the cost of enterprises.

Advantages of Using Cored Wire in Steelmaking

The use of cored wire in steelmaking offers advantages in terms of precision, efficiency, safety, and environmental impact. So more and more enterprises began to purchase core wire. Let’s take a look at its advantages.